Packaging for the Circular Economy

PopPack’s next generation design-tech solutions

By Cheryl E. Harrison

Just a few years ago, the Ellen MacArthur Foundation launched a worldwide initiative to build and expand global awareness in search of global solutions to reduce plastic packaging waste.

The concept of the Circular Economy tackles the dilemma of the entire life cycle of plastic materials from sourcing of materials and polymer films used to make plastic to ensure the best uses, re-uses, multi-uses and new uses of plastics so that plastics can be repurposed and reused throughout our global economy.

The initiative has expanded world-wide from Davos to Sri Lanka, and it’s called the “New Plastics Economy.” There’s much to be done in this area to achieve major ambitions and targeted goals. Certainly, there was more to be explored and commercially developed to meet this tall order.

There’s no silver bullet of what’s ecologically best.

Solutions are fast emerging in the field of bioplastics, which are coined bio-compostable, bio-degradable or bio-based. These may not be sustainable or commercially viable.

Yet, there is optimism for the more widespread development of films made of natural, bio-based materials – a blending of different bioplastics, and a combination of recycled components from conventional plastics, with films such as “rPET” (recycled polyethylene terephthalate) and bio-based “PET”, for example which are beginning to grow in popularity among packaging manufacturers and multinational brand owners.

There is an immediate promise and opportunity to convert a substantial volume of plastic waste into new pellets and polymers used for packaging. Post-consumer waste plastics can also be used for manufacturing industrial products, consumer products, roads, pavers, tiles, furniture, clothing, and other goods. Certain plastic waste streams may also convert to valuable energy.

Plastics and polymers should be created, by design to have a second, third or fourth life – – or possibly even a continuous life.

Infrastructure for processing waste plastics is limited and is very capital intensive. Dangers of toxic air emissions and waste streams, sorting out of hazardous materials from incineration, and poor recycling methods are onerous. The mixed combinations of hard plastics with soft, flexible plastics slow down the process substantially.

Heavy plastic jugs, hard plastic bottle caps and lids, plastic straws and loose plastic strips are typically separated in the waste streams. These loose plastic parts either go uncollected or are much too costly to recycle separately – so they are lost in streams and become abundant environmental waste and litter.

For these reasons, a very large percentage of plastics (about 65% in the USA; 48% in the EU; 40% in India) will never reach a recycling process. Japan’s solution is not to recycle, but rather to effectively collect and incinerate the majority of its collected plastic waste for energy conversion.

Packaging solutions, to substantially reduce plastic waste must be implemented at scale.

The Air-Powered Package® – Packaging designed for the Circular Economy

Over the past decade, PopPack, anticipated and invested to solve the exponential problem of plastic waste. Our mission was to design an entirely new category of package, with a design-first, and consumer-first approach.

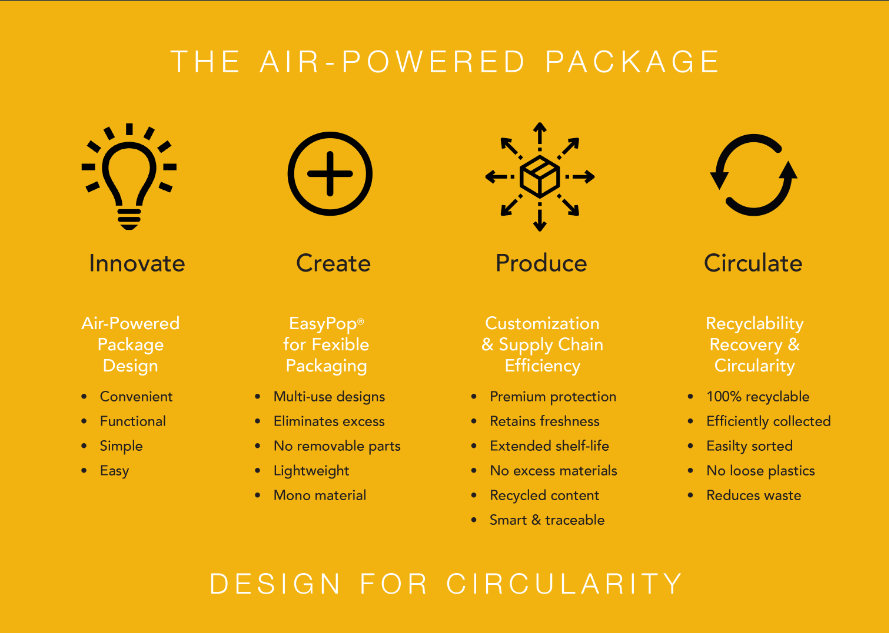

PopPack’s design-tech solution for the Air-Powered Package® is consistent with the Circular Economy as defined by the Ellen MacArthur Foundation as follows:

- Superior Design

- Customization

- Shared Design

- Smart Systems

- Compact products

- Deposit and Reward

Source: Reuse: Rethinking Packaging, The New Plastics Economy, Ellen MacArthur Foundation

Today, PopPack’s next generation packages are designed for the Circular Economy with a “universal, all-in-one solution” – commercially viable and exponentially scalable.

The design criteria that we set forth not only aligns with circularity standards set forth by the Ellen MacArthur’s New Plastics Economy, but also includes packaging design-tech to meet the Sustainable Development Goals (SDGs). PopPack’s next generation packages are uniquely designed – and inherently “exceptional,” with superior design and technologies made available through licensing and customization by leading brand owners and the packaging industry.

Plastic packaging made simple and circular.

Attributes of PopPack’s Air-Powered Package®…

- Simple, easy and appealing for the consumer to use – for all ages and abilities

- Easy to recycle, collect and sort, without loose, uncollected parts

- Cost-efficient to develop, produce, distribute and assure safety

- Adaptable for many purposes, different packaging functions, types, sizes and shapes

- Compact and lighter weight, with minimal use of supply chain resources

- Potential for multi-use functionality for packages that are single-use, while reducing waste

- Incorporates capabilities for interactive data and embedding smart technology

- Optimizes value chain efficiencies with e-commerce for direct-to-consumer delivery

- Customizable and scalable, especially for emerging and developed economies

PopPack’s ‘Air-Powered Package®’ provides an exceptional, innovative, design-driven approach for integrating design, technology and supply chain production for the Circular Economy. Its design-tech solution increases the value of plastic packaging throughout its circular life cycle.

PopPack is working in close partnership with both brand owners and the packaging industry – particularly packaging machinery companies and film manufacturers to help brand owners bring to market “circular packaging solutions” to meet the envisioned social and environmental targets and goals.

As we work closely with our new and existing partners to bring new EasyPop® packages to commercial markets, we hope to help pave the way for a new era of plastics with a cost-efficient new mode of local, and home-based sorting, recycling and pellet processing, whereby the entire package is fully collectible.

With EasyPop®, PopPack’s newly released “Air-Powered Package®”, the magic of air, polymers, nano science, smart sensors and interactive technologies, we will soon discover that the unsightly plastic waste of yesterday and today can be transformed to achieve circularity goals.

Specifically, we foresee a future where “smart” plastics with interconnected nano technologies embedded in the EasyPop® Air-Powered Package® will direct post-consumer packages to be automatically and safely sorted and shredded locally in our homes, schools, restaurants, communities and curbside recycling systems. Social and economic systems that encourage circularity will be enabled throughout the world – incentivizing many millions of waste-pickers in emerging countries to earn higher incomes through more effective, safer sorting for plastic waste re-use, with vastly improved production efficiencies.

In the years ahead, we will see plastic packaging transform into a valuable currency.

Plastic packaging is becoming “smart” and interactive. Packaging waste that is efficiently compacted and sorted will be more easily collected and converted to recycled polymer pellets. Waste packaging that is properly collected and sorted will provide environmentally safe energy, the creation of new high-performance durable materials, nutrients for our soils and so much more.

Those heaps and piles of unused plastic packaging waste and litter, we hope, will become a memory of the past. PopPack’s EasyPop® Air-Powered Package® is designed specifically for the circular economy to help the packaging industry move plastic packaging to higher supply chain value and asset.

Economic value = Net zero cost. Net zero waste.

The author, Cheryl E. Harrison, is a Co-Founder of PopPack LLC, a packaging design-tech company in San Francisco. Cheryl has a career in design for innovation and design for the consumer experience – with expertise in environmental and applied behavioral sciences. Her design-tech work focuses on developing packaging solutions for the circular economy to meet sustainability goals.

In September 2020, PopPack joined the U.S. Plastics Pact and the Plastics Pact, Netherlands to work on helping policies and actions move forward to achieve Circular Economy goals. PopPack is also a multi-year member of AIPIA, the Active and Intelligent Packaging Industry Association in the Netherlands.

PopPack has created EasyPop®, the ‘Air Powered Package®’ for consumer packaging. EasyPop® design-tech delivers sensory delight and engagement with convenience, simplicity, high-performance quality and eco-friendly efficiency – with a simple “pop” of an air bubble. EasyPop® is an all-in-one next generation packaging solution that is market-ready, and can be customized for liquid and solid products. EasyPop® is designed for consumers of all ages and abilities while also meeting goals for the circular economy. EasyPop® is licensed to brand owners and the industry by PopPack LLC in the USA, with marketing and commercial development by its affiliate, Vivia Ventures B.V. in the Netherlands.

PopPack®, EasyPop® and Air-Powered Package® are registered trademarks owned by PopPack LLC USA.

© PopPack LLC, all rights reserved.